Introduction: The Role of Steel Sheet in Everyday Structures

From buildings to vehicles, the steel sheet stands as a quiet hero behind strength and structure. This thin, flat metal form serves as a base material in countless industries. Builders, engineers, and fabricators all rely on steel sheet due to its strength, flexibility, and easy formability. Whether you're shaping a machine frame or creating a weather-resistant roof, steel sheet offers the perfect blend of durability and adaptability.

Understanding the Steel Sheet: Types and Traits

Key Properties

Thickness Variety: Available in different gauges, from thin foils to heavy-duty plates.

Formability: Easy to bend, press, or cut for custom projects.

Corrosion Resistance: Some sheets receive coatings or treatments to resist rust.

High Strength: Delivers solid performance even in extreme conditions.

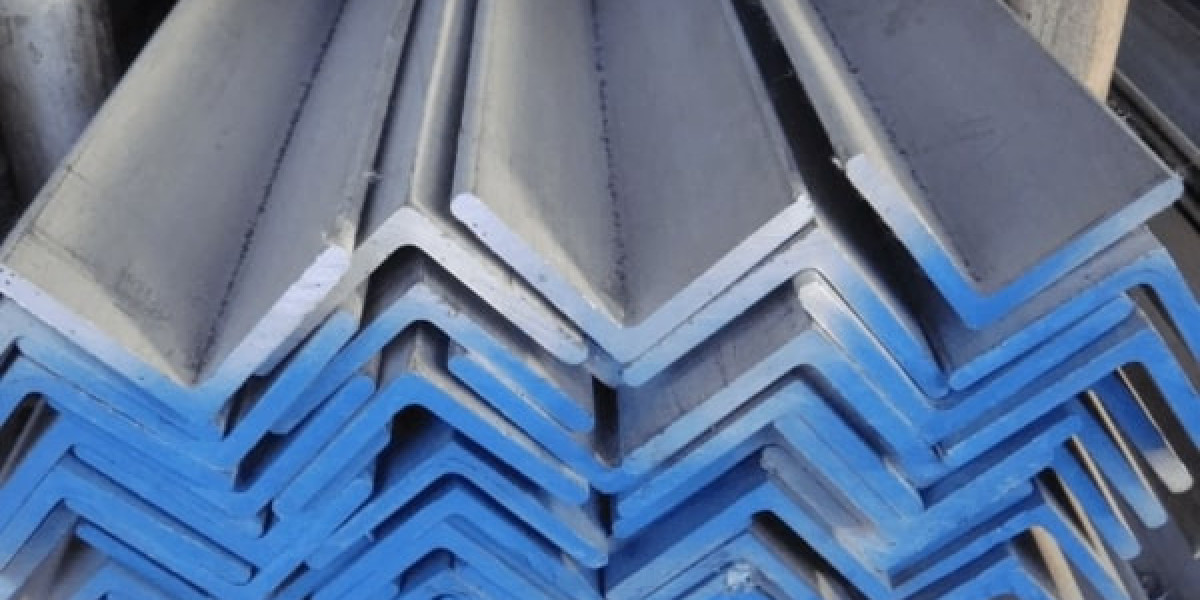

Angle Bar: Supporting Structures with Strength

Angle bar is an L-shaped steel section used widely for structural support. It adds stability to frames, platforms, and brackets. When paired with a steel sheet, the angle bar creates a strong skeleton for industrial or architectural applications.

How Angle Bar Complements Steel Sheet

Reinforces Edges: Adds support where flat sheets need strength.

Joins Surfaces: Forms strong corners or connections.

Boosts Load Capacity: Increases the durability of large panels.

Using angle bar alongside steel sheet ensures long-lasting performance in construction and fabrication.

Mild Steel: The Backbone of Everyday Engineering

Mild steel contains low carbon, making it strong yet easy to shape. It is the most common type of steel used in making steel sheet, due to its balance between cost and performance.

Why Mild Steel Matters

Weldable: Joins smoothly without cracking.

Flexible Strength: Holds its shape under stress.

Machinable: Responds well to drilling, cutting, and forming.

When you choose mild steel for a steel sheet, you get a material that fits many roles—from brackets to body panels—without adding weight or waste.

S355JR: Performance Under Pressure

S355JR is a structural grade steel known for its yield strength and toughness. It offers higher performance than regular mild steel, especially under heavy loads.

Features of S355JR Steel Sheet

High Yield Strength: Ideal for bridges, cranes, and towers.

Impact Tested: Resists sudden shock loads.

Structural Use: Performs in welded or bolted assemblies.

Choosing S355JR for steel sheet use guarantees reliability where safety and performance are critical.

Applications of Steel Sheet in Modern Projects

Steel sheet works across many sectors. From industrial frames to transport equipment, it adapts easily.

Where Steel Sheet Fits Best

Automotive Panels: Forms car doors, roofs, and chassis parts.

Building Roofs and Walls: Serves as cladding in high-rise structures.

Machinery: Covers, guards, and support panels in heavy machines.

Furniture Frames: Used in chairs, tables, and frames for added strength.

The thin yet tough nature of steel sheet gives it a unique ability to flex into these varied uses.

Choosing the Right Steel for Your Project

With options like mild steel, S355JR, and structural supports like angle bar, it’s vital to match material to need.

Quick Tips to Guide Selection

Check Load Requirements: Use S355JR if stress or impact is high.

Focus on Forming Needs: Choose mild steel for shaping and bending jobs.

Reinforce with Angle Bar: Add it where sheets might flex or sag.

Think Long-Term Use: Consider coatings or galvanised versions for weather exposure.

These decisions will influence cost, durability, and performance over time.

Caring for Steel Sheet: Maintenance Basics

Proper care increases the lifespan of any steel sheet project. Even tough metals need upkeep.

Simple Steps to Keep Steel Strong

Clean Regularly: Remove dust, dirt, or grease with mild soap.

Check for Rust: Treat spots early to stop spreading.

Apply Coatings: Use paint or anti-rust layers for protection.

Avoid Harsh Chemicals: Use safe products that won’t corrode the surface.

Caring for steel is not just about looks—it's about preserving its structural role.

Conclusion: Steel Sheet at the Core of Progress

From humble panels to major structural roles, the steel sheet stands at the centre of modern metalwork. With support from elements like the angle bar, and variations like mild steel and S355JR, this material offers unmatched flexibility. Whether shaping a product or supporting a skyscraper, steel remains the material of choice for smart builders and creative minds.

By knowing your materials, choosing wisely, and maintaining them with care, you ensure strength, safety, and success in every project.